I have programmed a heating cooling PID Controller for DL 06 PLC(Koyo / Direct Logic). It is not easy because using ladder logic to make a PID loop. And finally i have finished it.

Due to efficiency we have bought a Direct Logic PLC. DL 06 type is a cheap PLC. It is my first experiences.

I Selected the PID function in directsoft 5.3 and starting entering my addressing.

Loop 1

Table start address V1600

Setpoint Variable V1602

Process Variable V1603

Output V1605

I don't see anything in ladder logic. The PID loop operates outside of the PLC ladder logic. You can use ladder logic to interface with the PID loop. Most setups will use some ladder logic.

I have just copied from http://en.wikipedia.org/wiki/PID_controller. It is very useful for me to know how PID works.

A proportional–integral–derivative controller (PID controller) is a generic control loop feedback mechanism widely used in industrial control systems. A PID controller attempts to correct the error between a measured process variable and a desired setpoint by calculating and then outputting a corrective action that can adjust the process accordingly and rapidly, to keep the error minimal.

[edit] General

The PID controller calculation (algorithm) involves three separate parameters; the proportional, the integral and >derivative values. The proportional value determines the reaction to the current error, the integral value determines the reaction based on the sum of recent errors, and the derivative value determines the reaction based on the rate at which the error has been changing. The weighted sum of these three actions is used to adjust the process via a control element such as the position of a control valve or the power supply of a heating element.

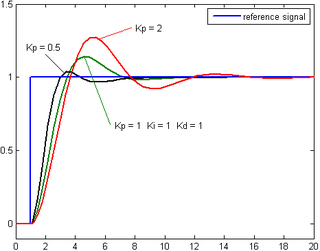

By tuning the three constants in the PID controller algorithm, the controller can provide control action designed for specific process requirements. The response of the controller can be described in terms of the responsiveness of the controller to an error, the degree to which the controller overshoots the setpoint and the degree of system oscillation. Note that the use of the PID algorithm for control does not guarantee optimal control of the system or system stability.

Some applications may require using only one or two modes to provide the appropriate system control. This is achieved by setting the gain of undesired control outputs to zero. A PID controller will be called a PI, PD, P or I controller in the absence of the respective control actions. PI controllers are particularly common, since derivative action is very sensitive to measurement noise, and the absence of an integral value may prevent the system from reaching its target value due to the control action.

Note: Due to the diversity of the field of control theory and application, many naming conventions for the relevant variables are in common use.

[edit] Control loop basics

A familiar example of a control loop is the action taken to keep one's shower water at the ideal temperature, which typically involves the mixing of two process streams, cold and hot water. The person feels the water to estimate its temperature. Based on this measurement they perform a control action: use the cold water tap to adjust the process. The person would repeat this input-output control loop, adjusting the hot water flow until the process temperature stabilized at the desired value.

Feeling the water temperature is taking a measurement of the process value or process variable (PV). The desired temperature is called the setpoint (SP). The output from the controller and input to the process (the tap position) is called the manipulated variable (MV). The difference between the measurement and the setpoint is the error (e), too hot or too cold and by how much.

As a controller, one decides roughly how much to change the tap position (MV) after one determines the temperature (PV), and therefore the error. This first estimate is the equivalent of the proportional action of a PID controller. The integral action of a PID controller can be thought of as gradually adjusting the temperature when it is almost right. Derivative action can be thought of as noticing the water temperature is getting hotter or colder, and how fast, anticipating further change and tempering adjustments for a soft landing at the desired temperature (SP).

Making a change that is too large when the error is small is equivalent to a high gain controller and will lead to overshoot. If the controller were to repeatedly make changes that were too large and repeatedly overshoot the target, the output would oscillate around the setpoint in either a constant, growing, or decaying sinusoid. If the oscillations increase with time then the system is unstable, whereas if they decay the system is stable. If the oscillations remain at a constant magnitude the system is marginally stable. A human would not do this because we are adaptive controllers, learning from the process history, but PID controllers do not have the ability to learn and must be set up correctly. Selecting the correct gains for effective control is known as tuning the controller.

If a controller starts from a stable state at zero error (PV = SP), then further changes by the controller will be in response to changes in other measured or unmeasured inputs to the process that impact on the process, and hence on the PV. Variables that impact on the process other than the MV are known as disturbances. Generally controllers are used to reject disturbances and/or implement setpoint changes. Changes in feed water temperature constitute a disturbance to the shower process.

In theory, a controller can be used to control any process which has a measurable output (PV), a known ideal value for that output (SP) and an input to the process (MV) that will affect the relevant PV. Controllers are used in industry to regulate temperature, pressure, flow rate, chemical composition, speed and practically every other variable for which a measurement exists. Automobile cruise control is an example of a process which utilizes automated control.

Due to their long history, simplicity, well grounded theory and simple setup and maintenance requirements, PID controllers are the controllers of choice for many of these applications.

PID controller theory

This section describes the parallel or non-interacting form of the PID controller. For other forms please see the Section "Alternative notation and PID forms".

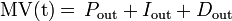

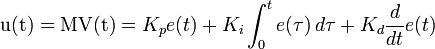

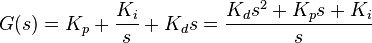

The PID control scheme is named after its three correcting terms, whose sum constitutes the manipulated variable (MV). Hence:

where

- Pout, Iout, and Dout are the contributions to the output from the PID controller from each of the three terms, as defined below.

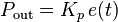

[edit] Proportional term

The proportional term (sometimes called gain) makes a change to the output that is proportional to the current error value. The proportional response can be adjusted by multiplying the error by a constant Kp, called the proportional gain.

The proportional term is given by:

where

- Pout: Proportional term of output

- Kp: Proportional gain, a tuning parameter

- e: Error = SP − PV

- t: Time or instantaneous time (the present)

A high proportional gain results in a large change in the output for a given change in the error. If the proportional gain is too high, the system can become unstable (See the section on loop tuning). In contrast, a small gain results in a small output response to a large input error, and a less responsive (or sensitive) controller. If the proportional gain is too low, the control action may be too small when responding to system disturbances.

In the absence of disturbances, pure proportional control will not settle at its target value, but will retain a steady state error that is a function of the proportional gain and the process gain. Despite the steady-state offset, both tuning theory and industrial practice indicate that it is the proportional term that should contribute the bulk of the output change.

[edit] Integral term

The contribution from the integral term (sometimes called reset) is proportional to both the magnitude of the error and the duration of the error. Summing the instantaneous error over time (integrating the error) gives the accumulated offset that should have been corrected previously. The accumulated error is then multiplied by the integral gain and added to the controller output. The magnitude of the contribution of the integral term to the overall control action is determined by the integral gain, Ki.

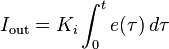

The integral term is given by:

where

- Iout: Integral term of output

- Ki: Integral gain, a tuning parameter

- e: Error = SP − PV

- t: Time or instantaneous time (the present)

- τ: a dummy integration variable

The integral term (when added to the proportional term) accelerates the movement of the process towards setpoint and eliminates the residual steady-state error that occurs with a proportional only controller. However, since the integral term is responding to accumulated errors from the past, it can cause the present value to overshoot the setpoint value (cross over the setpoint and then create a deviation in the other direction). For further notes regarding integral gain tuning and controller stability, see the section on loop tuning.

Derivative term

The rate of change of the process error is calculated by determining the slope of the error over time (i.e., its first derivative with respect to time) and multiplying this rate of change by the derivative gain Kd. The magnitude of the contribution of the derivative term (sometimes called rate) to the overall control action is termed the derivative gain, Kd.

The derivative term is given by:

where

- Dout: Derivative term of output

- Kd: Derivative gain, a tuning parameter

- e: Error = SP − PV

- t: Time or instantaneous time (the present)

The derivative term slows the rate of change of the controller output and this effect is most noticeable close to the controller setpoint. Hence, derivative control is used to reduce the magnitude of the overshoot produced by the integral component and improve the combined controller-process stability. However, differentiation of a signal amplifies noise and thus this term in the controller is highly sensitive to noise in the error term, and can cause a process to become unstable if the noise and the derivative gain are sufficiently large.

[edit] Summary

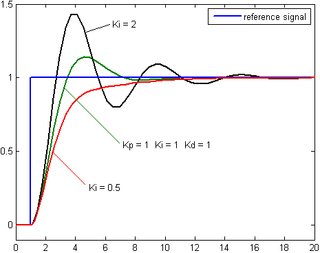

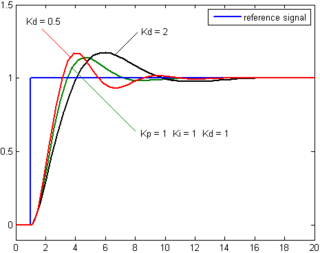

The proportional, integral, and derivative terms are summed to calculate the output of the PID controller. Defining u(t) as the controller output, the final form of the PID algorithm is:

where the tuning parameters are:

- Proportional gain, Kp

- larger values typically mean faster response since the larger the error, the larger the Proportional term compensation. An excessively large proportional gain will lead to process instability and oscillation.

- Integral gain, Ki

- larger values imply steady state errors are eliminated more quickly. The trade-off is larger overshoot: any negative error integrated during transient response must be integrated away by positive error before we reach steady state.

- Derivative gain, Kd

- larger values decrease overshoot, but slows down transient response and may lead to instability due to signal noise amplification in the differentiation of the error.

[edit] Loop tuning

If the PID controller parameters (the gains of the proportional, integral and derivative terms) are chosen incorrectly, the controlled process input can be unstable, i.e. its output diverges, with or without oscillation, and is limited only by saturation or mechanical breakage. Tuning a control loop is the adjustment of its control parameters (gain/proportional band, integral gain/reset, derivative gain/rate) to the optimum values for the desired control response.

The optimum behavior on a process change or setpoint change varies depending on the application. Some processes must not allow an overshoot of the process variable beyond the setpoint if, for example, this would be unsafe. Other processes must minimize the energy expended in reaching a new setpoint. Generally, stability of response (the reverse of instability) is required and the process must not oscillate for any combination of process conditions and setpoints. Some processes have a degree of non-linearity and so parameters that work well at full-load conditions don't work when the process is starting up from no-load. This section describes some traditional manual methods for loop tuning.

There are several methods for tuning a PID loop. The most effective methods generally involve the development of some form of process model, then choosing P, I, and D based on the dynamic model parameters. Manual tuning methods can be relatively inefficient.

The choice of method will depend largely on whether or not the loop can be taken "offline" for tuning, and the response time of the system. If the system can be taken offline, the best tuning method often involves subjecting the system to a step change in input, measuring the output as a function of time, and using this response to determine the control parameters.

| Choosing a Tuning Method | ||

| Method | Advantages | Disadvantages |

| Manual Tuning | No math required. Online method. | Requires experienced personnel. |

| Ziegler–Nichols | Proven Method. Online method. | Process upset, some trial-and-error, very aggressive tuning. |

| Software Tools | Consistent tuning. Online or offline method. May include valve and sensor analysis. Allow simulation before downloading. | Some cost and training involved. |

| Cohen-Coon | Good process models. | Some math. Offline method. Only good for first-order processes. |

[edit] Manual tuning

If the system must remain online, one tuning method is to first set Ki and Kd values to zero. Increase the Kp until the output of the loop oscillates, then the Kp should be left set to be approximately half of that value for a "quarter amplitude decay" type response. Then increase Ki until any offset is correct in sufficient time for the process. However, too much Ki will cause instability. Finally, increase Kd, if required, until the loop is acceptably quick to reach its reference after a load disturbance. However, too much Kd will cause excessive response and overshoot. A fast PID loop tuning usually overshoots slightly to reach the setpoint more quickly; however, some systems cannot accept overshoot, in which case an "over-damped" closed-loop system is required, which will require a Kp setting significantly less than half that of the Kp setting causing oscillation.

| Effects of increasing parameters | ||||

| Parameter | Rise time | Overshoot | Settling time | Error at equilibrium |

| Kp | Decrease | Increase | Small change | Decrease |

| Ki | Decrease | Increase | Increase | Eliminate |

| Kd | Indefinite (small decrease or increase)[1] | Decrease | Decrease | None |

[edit] Ziegler–Nichols method

Another tuning method is formally known as the Ziegler–Nichols method, introduced by John G. Ziegler and Nathaniel B. Nichols. As in the method above, the Ki and Kd gains are first set to zero. The P gain is increased until it reaches the critical gain, Kc, at which the output of the loop starts to oscillate. Kc and the oscillation period Pc are used to set the gains as shown:

| Ziegler–Nichols method | ||||

| Control Type | Kp | Ki | Kd | |

| P | 0.50Kc | - | - | |

| PI | 0.45Kc | 1.2Kp / Pc | - | |

| PID | 0.60Kc | 2Kp / Pc | KpPc / 8 | |

[edit] PID tuning software

Most modern industrial facilities no longer tune loops using the manual calculation methods shown above. Instead, PID tuning and loop optimization software are used to ensure consistent results. These software packages will gather the data, develop process models, and suggest optimal tuning. Some software packages can even develop tuning by gathering data from reference changes.

Mathematical PID loop tuning induces an impulse in the system, and then uses the controlled system's frequency response to design the PID loop values. In loops with response times of several minutes, mathematical loop tuning is recommended, because trial and error can literally take days just to find a stable set of loop values. Optimal values are harder to find. Some digital loop controllers offer a self-tuning feature in which very small setpoint changes are sent to the process, allowing the controller itself to calculate optimal tuning values.

Other formulas are available to tune the loop according to different performance criteria.

[edit] Modifications to the PID algorithm

The basic PID algorithm presents some challenges in control applications that have been addressed by minor modifications to the PID form.

One common problem resulting from the ideal PID implementations is integral windup. This problem can be addressed by:

- Initializing the controller integral to a desired value

- Increasing the setpoint in a suitable ramp

- Disabling the integral function until the PV has entered the controllable region

- Limiting the time period over which the integral error is calculated

- Preventing the integral term from accumulating above or below pre-determined bounds

- Freezing the integral function in case of disturbances

- If a PID loop is used to control the temperature of an electric resistance furnace, the system has stabilized and then the door is opened and something cold is put into the furnace the temperature drops below the setpoint. The integral function of the controller tends to compensate this error by introducing another error in the positive direction. This can be avoided by freezing of the integral function after the opening of the door for the time the control loop typically needs to reheat the furnace.

- Replacing the integral function by a model based part

- Often the time-response of the system is approximately known. Then it is an advantage to simulate this time-response with a model and to calculate some unknown parameter from the actual response of the system. If for instance the system is an electrical furnace the response of the difference between furnace temperature and ambient temperature to changes of the electrical power will be similar to that of a simple RC low-pass filter multiplied by an unknown proportional coefficient. The actual electrical power supplied to the furnace is delayed by a low-pass filter to simulate the response of the temperature of the furnace and then the actual temperature minus the ambient temperature is divided by this low-pass filtered electrical power. Then, the result is stabilized by another low-pass filter leading to an estimation of the proportional coefficient. With this estimation it is possible to calculate the required electrical power by dividing the set-point of the temperature minus the ambient temperature by this coefficient. The result can then be used instead of the integral function. This also achieves a control error of zero in the steady-state but avoids integral windup and can give a significantly improved control action compared to an optimized PID controller. This type of controller does work properly in an open loop situation which causes integral windup with an integral function. This is an advantage if for example the heating of a furnace has to be reduced for some time because of the failure of a heating element or if the controller is used as an advisory system to a human operator who may or may not switch it to closed-loop operation or if the controller is used inside of a branch of a complex control system where this branch may be temporarily inactive.

Many PID loops control a mechanical device (for example, a valve). Mechanical maintenance can be a major cost and wear leads to control degradation in the form of either stiction or a deadband in the mechanical response to an input signal. The rate of mechanical wear is mainly a function of how often a device is activated to make a change. Where wear is a significant concern, the PID loop may have an output deadband to reduce the frequency of activation of the output (valve). This is accomplished by modifying the controller to hold its output steady if the change would be small (within the defined deadband range). The calculated output must leave the deadband before the actual output will change.

The proportional and derivative terms can produce excessive movement in the output when a system is subjected to an instantaneous step increase in the error, such as a large setpoint change. In the case of the derivative term, this is due to taking the derivative of the error, which is very large in the case of an instantaneous step change. As a result, some PID algorithms incorporate the following modifications:

- Derivative of output

- In this case the PID controller measures the derivative of the output quantity, rather than the derivative of the error. The output is always continuous (i.e., never has a step change). For this to be effective, the derivative of the output must have the same sign as the derivative of the error.

- Setpoint ramping

- In this modification, the setpoint is gradually moved from its old value to a newly specified value using a linear or first order differential ramp function. This avoids the discontinuity present in a simple step change.

- Setpoint weighting

- Setpoint weighting uses different multipliers for the error depending on which element of the controller it is used in. The error in the integral term must be the true control error to avoid steady-state control errors. This affects the controller's setpoint response. These parameters do not affect the response to load disturbances and measurement noise.

[edit] Limitations of PID control

While PID controllers are applicable to many control problems, they can perform poorly in some applications.

PID controllers, when used alone, can give poor performance when the PID loop gains must be reduced so that the control system does not overshoot, oscillate or hunt about the control setpoint value. The control system performance can be improved by combining the feedback (or closed-loop) control of a PID controller with feed-forward (or open-loop) control. Knowledge about the system (such as the desired acceleration and inertia) can be fed forward and combined with the PID output to improve the overall system performance. The feed-forward value alone can often provide the major portion of the controller output. The PID controller can then be used primarily to respond to whatever difference or error remains between the setpoint (SP) and the actual value of the process variable (PV). Since the feed-forward output is not affected by the process feedback, it can never cause the control system to oscillate, thus improving the system response and stability.

For example, in most motion control systems, in order to accelerate a mechanical load under control, more force or torque is required from the prime mover, motor, or actuator. If a velocity loop PID controller is being used to control the speed of the load and command the force or torque being applied by the prime mover, then it is beneficial to take the instantaneous acceleration desired for the load, scale that value appropriately and add it to the output of the PID velocity loop controller. This means that whenever the load is being accelerated or decelerated, a proportional amount of force is commanded from the prime mover regardless of the feedback value. The PID loop in this situation uses the feedback information to effect any increase or decrease of the combined output in order to reduce the remaining difference between the process setpoint and the feedback value. Working together, the combined open-loop feed-forward controller and closed-loop PID controller can provide a more responsive, stable and reliable control system.

Another problem faced with PID controllers is that they are linear. Thus, performance of PID controllers in non-linear systems (such as HVAC systems) is variable. Often PID controllers are enhanced through methods such as PID gain scheduling or fuzzy logic. Further practical application issues can arise from instrumentation connected to the controller. A high enough sampling rate, measurement precision, and measurement accuracy are required to achieve adequate control performance.

A problem with the Derivative term is that small amounts of measurement or process noise can cause large amounts of change in the output. It is often helpful to filter the measurements with a low-pass filter in order to remove higher-frequency noise components. However, low-pass filtering and derivative control can cancel each other out, so reducing noise by instrumentation means is a much better choice. Alternatively, the differential band can be turned off in many systems with little loss of control. This is equivalent to using the PID controller as a PI controller.

[edit] Cascade control

One distinctive advantage of PID controllers is that two PID controllers can be used together to yield better dynamic performance. This is called cascaded PID control. In cascade control there are two PIDs arranged with one PID controlling the set point of another. A PID controller acts as outer loop controller, which controls the primary physical parameter, such as fluid level or velocity. The other controller acts as inner loop controller, which reads the output of outer loop controller as set point, usually controlling a more rapid changing parameter, flowrate or acceleration. It can be mathematically proven[citation needed] that the working frequency of the controller is increased and the time constant of the object is reduced by using cascaded PID controller.[vague].

[edit] Physical implementation of PID control

In the early history of automatic process control the PID controller was implemented as a mechanical device. These mechanical controllers used a lever, spring and a mass and were often energized by compressed air. These pneumatic controllers were once the industry standard.

Electronic analog controllers can be made from a solid-state or tube amplifier, a capacitor and a resistance. Electronic analog PID control loops were often found within more complex electronic systems, for example, the head positioning of a disk drive, the power conditioning of a power supply, or even the movement-detection circuit of a modern seismometer. Nowadays, electronic controllers have largely been replaced by digital controllers implemented with microcontrollers or FPGAs.

Most modern PID controllers in industry are implemented in programmable logic controllers (PLCs) or as a panel-mounted digital controller. Software implementations have the advantages that they are relatively cheap and are flexible with respect to the implementation of the PID algorithm.

[edit] Alternative nomenclature and PID forms

[edit] Ideal versus standard PID form

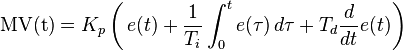

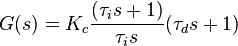

The form of the PID controller most often encountered in industry, and the one most relevant to tuning algorithms is the standard form. In this form the Kp gain is applied to the Iout, and Dout terms, yielding:

where

- Ti is the integral time

- Td is the derivative time

In the ideal parallel form, shown in the controller theory section

the gain parameters are related to the parameters of the standard form through  and

and  . This parallel form, where the parameters are treated as simple gains, is the most general and flexible form. However, it is also the form where the parameters have the least physical interpretation and is generally reserved for theoretical treatment of the PID controller. The standard form, despite being slightly more complex mathematically, is more common in industry.

. This parallel form, where the parameters are treated as simple gains, is the most general and flexible form. However, it is also the form where the parameters have the least physical interpretation and is generally reserved for theoretical treatment of the PID controller. The standard form, despite being slightly more complex mathematically, is more common in industry.

[edit] Laplace form of the PID controller

Sometimes it is useful to write the PID regulator in Laplace transform form:

Having the PID controller written in Laplace form and having the transfer function of the controlled system, makes it easy to determine the closed-loop transfer function of the system.

[edit] Series/interacting form

Another representation of the PID controller is the series, or interacting form

where the parameters are related to the parameters of the standard form through

,

,  , and

, and

with

.

.

This form essentially consists of a PD and PI controller in series, and it made early (analog) controllers easier to build. When the controllers later became digital, many kept using the interacting form.

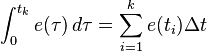

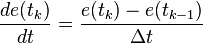

[edit] Discrete implementation

The analysis for designing a digital implementation of a PID controller in a Microcontroller (MCU) or FPGA device requires the standard form of the PID controller to be discretised [2]. Approximations for first-order derivatives are made by backward finite differences. The integral term is discretised, with a sampling time Δt,as follows,

The derivative term is approximated as,

Thus, a velocity algorithm for implementation of the discretised PID controller in a MCU is obtained,

[edit] Pseudocode

Here is a simple software loop that implements the PID algorithm:

previous_error = 0 integral = 0 start: error = setpoint - actual_position integral = integral + (error*dt) derivative = (error - previous_error)/dt output = (Kp*error) + (Ki*integral) + (Kd*derivative) previous_error = error wait(dt) goto start

[edit] External links

[edit] PID tutorials

- PID Tutorial

- P.I.D. Without a PhD: a beginner's guide to PID loop theory with sample programming code

- What's All This P-I-D Stuff, Anyhow? Article in Electronic Design

- Shows how to build a PID controller with basic electronic components (pg. 22)

[edit] Simulations

- Free, real-time PID simulator for Windows

- PID controller using MatLab and Simulink

- PID controller laboratory, Java applets for PID tuning

[edit] Special topics and PID control applications

- Proven Methods and Best Practices for PID Control

- PID Control Primer Article in Embedded Systems Programming

[edit] References

- ^ http://saba.kntu.ac.ir/eecd/pcl/download/PIDtutorial.pdf

- ^ http://www.scribd.com/doc/19070283/Discrete-PI-and-PID-Controller-Design-and-Analysis-for-Digital-Implementation

- Liptak, Bela (1995). Instrument Engineers' Handbook: Process Control. Radnor, Pennsylvania: Chilton Book Company. pp. 20–29. ISBN 0-8019-8242-1.

- Tan, Kok Kiong; Wang Qing-Guo, Hang Chang Chieh (1999). Advances in PID Control. London, UK: Springer-Verlag. ISBN 1-85233-138-0.

- Van, Doren, Vance J. (July 1, 2003). "Loop Tuning Fundamentals". Control Engineering (Red Business Information). http://www.controleng.com/article/CA307745.html.

- Sellers, David. "An Overview of Proportional plus Integral plus Derivative Control and Suggestions for Its Successful Application and Implementation" (PDF). http://www.peci.org/library/PECI_ControlOverview1_1002.pdf. Retrieved 2007-05-05.

- Graham, Ron (10/03/2005). "FAQ on PID controller tuning". http://web.archive.org/web/20050206113949/www.tcnj.edu/~rgraham/PID-tuning.html. Retrieved 2009-01-05.

![u(t_k)=u(t_{k-1})+K_p\left[\left(1+\dfrac{\Delta t}{T_i}+\dfrac{T_d}{\Delta t}\right)e(t_k)+\left(-1-\dfrac{2T_d}{\Delta t}\right)e(t_{k-1})+\dfrac{T_d}{\Delta t}e(t_{k-2})\right]](http://upload.wikimedia.org/math/a/9/b/a9beb5ee392aa86e76d734e9e761b148.png)

Dear ALL

Sorry i am just copied from wikipedia

jian tenan.....

buku berjalan PID rek....

aku diurui po'o....

lengkap poll.. nganti rak mudeng blas aku... hihihi

mantap nih...

sebuah referensi yang lengkapppp...

Cocok buat referensi belajar nih...

bro.... pelan2 dong, mumet nich kepala ngikutinnya.

ada yg PDF nya gak bro, biar numpang sedot aja ke komputer :)

hihihihihi

tq

bos admin (Endri) saya numpang copy ya, buat referensi dan menambah koleksi di pustaka teman :)

May I have a copy of your article?

that's will be good for my reference on my website.

That technical articles. The internet world will be rich with your mechanical articles. keep writing brother, I'm sure this blog will bigger one day couse focused to one niche.

@mortgage refinancing.

thank you very much for your inspiring.

i hope that your blog will bigger too.

Really good blog and new information for me.

_____________________________

Visit : http://www.electricalquizzes.com for free objective type questions related to Electrical Engineering.

_____________________________

NENGA HUA GOOR DDIEETYS pdf CHEPU MIODKI KI

Excellent men thanks for the manual It's very nice and it just help me with my job, thanks for share.

At the beginning I thought the post was not interesting, but I have to say I was intrigued with this theme. After read the information you posted, and to see the way you did it, I change my opinion and I started to feel curiosity for your other entries, so I decided to read them all one by one. Now, I have to say it became in one of the greatest blogs I have read in my entire life.

Honestly to say your explanation is so complete and make the reader can understand the topic easily.

Thanks

Thank you for the brief and complete information

kontroling a good time yaaa

kontroling a good time yaaa

kontroling a good time yaaa

kontroling a good time yaaa

tank inp0nya ijin copas ilmunya

Thanks for the very comprehensive tutorial. I'm actually going to use this for one part of my thesis. Very useful, I really appreciate it :)

walaahh pusing nih :D

mantap gan komplit banget, LANJUTKAN gan :D

mantap gan infonya makasih untuk infonya

ini tuh pemogramannya pake PLC mas?

nice share, thanks for share :D

Those look like very complicated calculations. This post was very informative and I at least now have an idea on how PID works.

Your blog is very motivating. When I was reading it, I get drawn in. I am totally agreed with your thoughts. Thanks for sharing this beautiful thoughts with me.

informasi yg top nich

postingannya keren gan mantap dah..

artikel yg menarik. sukses slalu

Nice term papers service writer. Help with writing.Buy essay. Good essay sample.

Nice Share :D

Visit Back :D

Buy papers online , help with writing , how to write essay .

Dissertation writing services ,dissertations , dissertations online ,best dissertation , buy dissertation .

apa itu bos? ora ngerti blas

Exceptionally useful article. Myself & my neighbor were preparing to do some research about that. We got a beneficial book on that matter from our local library and most books were not as descriptive as your information. I'm pretty glad to see such information which I was searching for a long time.

goood,,,,,

Loh dari wikipedia toh.. hehehe

Tapi bagus koq Mas...

One unique benefits of PID remote controls is that two PID remote controls can be used together to generate better energetic efficiency. This is known as cascaded PID management. In stream management there are two PIDs organized with one PID managing the set factor of another.

Thanks a lot for sharing this amazing knowledge with us. This site is fantastic. I always find great knowledge from it.

Very informative and inspiring. Thanks for sharing.

Healthy Green provides the finest Natural supplements, organic supplements and Medicinal vitamins. No fillers, binders, or chemical excipients.

organic supplements

=|=natural supplements

=|=organic vitamins

tubal reversal | tubal ligation reversal | tubal reversal surgery

Hey great stuff, thank you for sharing this useful information and I will let know my friends as well.

Very significant article for us ,I think the representation of this article is

actually superb one. This is my first visit to your site

Did you know that some synthetic vitamin supplements can actually be harmful to your health. You choice of multivitamin and multi-mineral supplements is not something you should take lightly.

This is good site to spent time on .I just stumbled upon your informative blog and wanted to say that I have really enjoyed reading your very well written blog posts. I will be your frequent visitor, that's for sure.

siiippp... keren gan infonya... Happy Blog walkiing....

Thanks for sharing ideas and thought,I like you blog and bookmark this blog for further use.

You provided a valuable service to the community. Thank you for doing such a great job all these years.

Hello Dear,

Really your blog is very interesting.... it contains great and unique information. I enjoyed to visiting your blog. It's just amazing.... Thanks very much

You’ve written nice post, I am gonna bookmark this page, thanks for info. I actually appreciate your own position and I will be sure to come back here.

Certainly a fantastic piece of work ... It has relevant information. Thanks for posting this. Your blog is so interesting and very informative.Thanks sharing. Definitely a great piece of work Thanks for your work.

A healthy diet is not about strict nutrition philosophies, staying extremely thin, or depriving yourself of foods you love. Rather it is to get that good to have more energy and you keep healthy as possible.

Wonderful post. I am searching awesome news and idea. What I have found from your site, it is actually highly content. You have spent long time for this post. It's a very useful and interesting site. Thanks!

Thanks for your many years of a great service well done! I’ve always felt good about listing my concerts with you and linking from my website.

This is like my fourth time stopping over. Normally, I do not make comments on website, but I have to mention that this post really pushed me to do so. Really great post

With the many blogs which I have encountered, I never expected to see a very beautiful post online..After viewing this one, I felt so lucky to see its content.:)

VERY clever, I would never have thought of re-creating spaghetti-0's, but I'll bet the grandkids will love them.

I like your post. It is good to see you verbalize from the heart and clarity on this important subject can be easily observed.

Incredible information. thanks for the information

I am absolutely amazed at how terrific the stuff is on this site. I have saved this webpage and I truly intend on visiting the site in the upcoming days. Keep up the excellent work.

I will be there for sure for an entire semester next autumn. I hope to make some virtual friends until then.

Thanks for sharing such a excellent post.I need to say really thank you for this terrific information. now i recognize about it

I recently came across your blog and have been reading along. I thought I clubmz reviews would leave my first comment. I don’t know what to say except that I have enjoyed reading

I really enjoy simply reading all of your weblogs. Simply wanted to inform you that you have people like me who appreciate your work. Definitely a great post. Hats off to you! The information that you have provided is very helpful.

I have no words to appreciate this post ..... I'm really impressed with this post .... the person who created this post was a big thank you man .. for sharing with us.

towing in richardson

The post is written in very a good manner and it entails many useful information for me. Thanks for sharing the information

I really enjoy simply reading all of your weblogs. Simply wanted to inform you that you have people like me who appreciate your work. Definitely a great post. Hats off to you! The information that you have provided is very helpful.

Wow!! What a great writing, really I appreciate such kind of topics. It will be very helpful for us. Waiting for more articles, blogs like this. I’m going bookmark your blog for future reference. Thanks a lot for sharing this.

Towing service in frisco

Thank you for for sharing so great thing to us. I definitely enjoying every little bit of it I have you bookmarked to check out new stuff you post nice post, thanks for sharing.

This is an excellent post I seen thanks to share it. It is really what I wanted to see hope in future you will continue for sharing such a excellent post

I am happy when reading your blog with updated information! thanks alot and hope that you will post more site that are related to this site.

A friend of mine visits your blog quite often and recommended it to me to read too. The writing style is solid and the content is pertinent. Thank you for the insight you provide the subscribers!

Thank you for sharing so great thing to us. I definitely enjoying every little bit of it I have you bookmarked to check out new stuff you post nice post, thanks for sharing.

I used to be more than happy to seek out this internet-site.I wanted to thanks in your time for this glorious read!! I positively enjoying each little bit of it and I have you bookmarked to check out new stuff you weblog post.

Excellent article! It’s apparent you’ve gone to a lot of trouble to research and write this article. Thanks for caring so much about your content.

I am happy when reading your blog with updated information! thanks alot and hope that you will post more site that are related to this site.

This article left me very impressed. I was surfing the Internet directly, until I found this concept very useful and article.The your message is very special is a good factor to attract more visitors to read your site! Thanks.

This kind of post is very rare.. its so hard to seek a post like this. very informative and the contents are very Obvious and Concise .I will look more of your post.

Thanks for sharing such a excellent post.I need to say really thank you for this terrific information. now i recognize about it.

hi .. great web blog nice formula's that can help engineering students and much informative great uploading ....

gift to Pakistan

This article is well written and very informative. I really like this site because it offers loads of information to its followers.

Hi buddy, your blog's design is simple and clean and i like it. Your blog posts are superb. Please keep them coming. Greets!!!

You are a Great while writing in the blogs it is awesome I liked it too much good and informative thanks for the sharing.

Thank you for posting.Very well written.Waiting for updating.

I enjoyed reading your articles. This is truly a great read for me. I have bookmarked it and I am looking forward to reading new articles. thanks.

I think the natural and biological sources of vitamins and minerals are best compared with other packaging and plastic products. Always try to push things you need in your home. It is not only going to be cheaper, but it will be much more beneficial to your health and your family.

Towing in dallas

Great write up, bookmarked your website with interest to read more information!

_______________

Essay Writing || dissertation writing services ||

College essay writing || Letter writing services ||

Professional Essay Writing || term paper writing service

Wonderful site and I wanted to post a note to let you know, ""Good job""! I’m glad I found this blog. Brilliant and wonderful job ! Your blog site has presented me most of the strategies which I like. Thanks for sharing this.

best organic seo company

Valuable information for all. And of course nice review about the application. It contains truly information. Your website is very useful. Thanks for sharing. Looking forward to more!

I really enjoy simply reading all of your weblogs. Simply wanted to inform you that you have people like me who appreciate your work. Definitely a great post. Hats off to you! The information that you have provided is very helpful.

Thanks to a brilliant effort in publishing your article. One can be more informative as this. There are many things I can know only after reading your wonderful article.

This is the right blog for anyone who wants to find out about this topic. You realize so much its almost hard to argue with you (not that I actually would want…HaHa). You definitely put a new spin on a topic thats been written about for years. Great stuff, just great! presupuesto pagina web

This is better than other sites.Always so interesting to visit your site.What a great info

Thank you for this club e-spy blog. That's all I can say. You most definitely have made this blog into something that's eyes opening

Good and different updates. You have described many information in one post. Now only I have got it. Thanks for sharing...

thank you for sharing. this will help me so much in my learning.

Your blog article is very interesting and fantastic, at the same time the blog theme is unique and perfect, great job. To your success. One of the more impressive blogs I’ve seen.

I wish to be a part of this concert. Thanks for writing the review

I enjoy a couple of from the articles which have been written, and particularly the comments posted! I will definitely be visiting again!

Sometimes strong is not what good things, because some people will think you strong, therefore I hurt no problems, then again and again to hurt you.

I agree with you. This post is truly inspiring. I like your post and everything you share with us is current and very informative, I want to bookmark the page so I can return here from you that you have done a fantastic job ...

That brought me a thought that turned my envy into joy. Our adventures are not so much in our travels as in our experiences and we can experience every day.

Thanks for taking the time to discuss this, I feel strongly that love and read more on this topic. If possible, such as gain knowledge, would you mind updating your blog with additional information? It is very useful for me

Thank you for sharing it with us. Hey, your blog is great. I will bookmark it and I plan to visit regularl

What an amazing blog. I have found this blog very interesting because I have gotten the most read information. This blog help me out otherwise I don’t know how much time I have to spend for getting right information..

It was really exceptionally impressive. Updating an application requires a skeptical work and lot of patience, but with the help pf this post many of the users would be guided onto the proper way of updating a software.

This web site is really a walk-through for all of the info you wanted about this and didn’t know who to ask. Glimpse here, and you’ll definitely discover it.

Thanks to a brilliant effort in publishing your article. One can be more informative as this. There are many things I can know only after reading your wonderful article.

There are many things I can know only after reading your wonderful article.

The best site online pharmacy which gives us good information about the medicines.. and its cheap too..

Thanks for great information you write it very clean. I am very lucky to get this tips from you.

nice and great post.in a word, unique and fine piece of information. I've never spent that much time reading before but this is really awesome.I definitely want to read more on that blog soon.so i will visit here very soon for next post.thanks.

This is an excellent post. I learned a lot about what you talking about. Not sure if I agree with you completely though.

I really enjoy simply reading all of your weblogs. Simply wanted to inform you that you have people like me who appreciate your work. Definitely a great post. Hats off to you! The information that you have provided is very helpful.ofertas paintball www.bomjuegos.com/juegos-de-futbol

This is an excellent post. I learned a lot about what you talking about. Not sure if I agree with you completely though.

nice and great post.in a word, unique and fine piece of information. I've never spent that much time reading before but this is really awesome.I definitely want to read more on that blog soon.so i will visit here very soon for next post.thanks.

Thanks to a brilliant effort in publishing your article. One can be more informative as this. There are many things I can know only after reading your wonderful article.executive resume writer

Thanks for great information you write it very clean. I am very lucky to get this tips from you.

I got here much interesting stuff. The post is great!

Really appreciate this wonderful post that you have provided for us.Great site and a great topic as well i really get amazed to read this.

I am very impressed to your blog you did a very hard work. and I really appreciate you to sharing such a useful post, Great Job!

nice and great post.in a word, unique and fine piece of information. I've never spent that much time reading before but this is really awesome.I definitely want to read more on that blog soon.so i will visit here very soon for next post.thanks.

I completely agree with you. I have no point to raise in against of what you have said I think you explain the whole situation very well.

Thanks for this informative post. It help me a lot. And it gave mo ideas on how to make more money in marketing business. I hope lots of people visit this site so they can easily learn this informative post.

Thanks for this informative post. It help me a lot. And it gave mo ideas on how to make more money in marketing business. I hope lots of people visit this site so they can easily learn this informative post.

Absolutely fantastic posting! Lots of useful information and inspiration, both of which we all need!Relay appreciate your work.

Very good customer service, prompt delivery (lol...prompt for coming from so far away!), and good products. I recommend this company to my friends all the time. is a godsend to those of us without medical insurance.

dallas towing

So informative and interesting post have been shared here.It's very nice website. I will search this page again & again great list. I appreciate your efforts to bring such a huge list for us.

This is my favorite blog. I have never gone disappointed from here. There is always something new to learn.

I really enjoyed the quality information you offer to your visitors for this blog. I will bookmark your blog and have my friends check up here often.

Certainly a fantastic piece of work ... It has relevant information. Thanks for posting this. Your blog is so interesting and very informative.Thanks sharing. Definitely a great piece of work Thanks for your work.

moving companies washington dc

I really wonder the present condition of world economy.It has gradually improved through internet.I hope people will also feel this change and take it with great consideration.

Hi! This is my first visit to your blog! We are a team of volunteers and new initiatives in the same niche. Blog gave us useful information to work. You have done an amazing job!

change locks

I am not very good in academic papers proofreading. However, I always need Research Paper Guidelines. Probably, someone can assist me?

Thank you for useful information. It is exactly what I needed. I managed to get here everything that I need for my article. Applause for a author!

Interesting post. It is however very helpful and I am sure it has helped a lot of people who were interested in installing this.

I am not very good in academic papers proofreading. However, I always need Research Paper Guidelines. Probably, someone can assist me?

i cant stop it on my wordpress site, drives me crazy always reportingtrackback spam as spam.

essay writing services

4.10.2012 13:34

This is like my fourth time stopping over your Blog. Normally, I do not make comments on website, but I have to mention that this post really pushed me to do so. Really great post .

I have no words to appreciate this post ..... I'm really impressed with this post .... the person who created this post was a big thank you man .. for sharing with us.

Really your blog is very interesting.... it contains great and unique information. I enjoyed to visiting your blog. It's just amazing.... Thanks very much

The proportional value determines the reaction to the current error,

Hey great stuff, thank you for sharing this useful information and i will let know my friends as well.

movers washington dc

anak robotika harus pelajarin ini PID, penting banget buat responsive system yang punya feedback biar system jadi stabil

This web site is really a walk-through for all of the info you wanted about this and didn’t know who to ask. Glimpse here, and you’ll definitely discover it.

Hey great stuff, thank you for sharing this useful information and i will let know my friends as well.

anak robotika harus pelajarin ini PID, penting banget buat responsive system yang punya feedback biar system jadi stabil

Great blog. All posts have something to learn. Your work is very good and i appreciate you and hopping for some more informative posts.

We recommend that you do not click on any email links purporting to regard this breach. "

This is a great blog posting and very useful. I really appreciate the research you put into it...

The web is so full of garbage it's becoming difficult to find exactly what you are looking for nowadays

That is a very well written article. I will be sure to bookmark it and return to learn more of your useful info. Thanks for the post.

Such intelligent work and reporting! Keep up the excellent works guys I've incorporated you guys to my blogroll.

I really enjoy simply reading all of your weblogs. Simply wanted to inform you that you have people like me who appreciate your work. Definitely a great post. Hats off to you! The information that you have provided is very helpful.

Really good read for me, Must admit that you are one of the best bloggers I ever saw.Thanks for posting this informative article.

Steel wool or a steel brush, worked in a circular motion, will give new luster to tin or metal. For brass, use a polish to restore the shine. However, replacing the hardware may be the best decision if you are concerned about utility rather than restoration. Thanks a lot.

that was rellay good article man, thanks

That is very interesting Smile I love reading and I am always searching for informative information like this. This is exactly what I was looking for. Thanks for sharing this great article.

lengkap bnr....ampe pusing liatnya..

thx bro...saya coba step by step...

This web site is really a walk-through for all of the info you wanted about this and didn’t know who to ask.Certainly a fantastic piece of work ... It has relevant information. Thanks for posting this.

The clarity in your post is simply spectacular and I can assume you are an expert on this field. Well with your permission allow me to grab your rises feed to keep up to date with incoming post.

This is a great article connected with this good post. Guys want to have such great writing abilities. But they have to purchase the dissertations proposed by the professional thesis writing service.

That is very interesting Smile I love reading and I am always searching for informative information like this. This is exactly what I was looking for. Thanks for sharing this great article.

I really enjoy simply reading all of your weblogs. Simply wanted to inform you that you have people like me who appreciate your work. Definitely a great post. Hats off to you! The information that you have provided is very helpful.

The weighted sum of these three actions is used to adjust the process via a control element such as the position of a control valve or the power supply of a heating element.

The combination of informative and quality content is certainly extremely rare with the large amount of blogs on the internet.i found it informative and interesting. Looking forward for more

updates. revision de puente grua

That is very interesting Smile I love reading and I am always searching for informative information like this. This is exactly what I was looking for. Thanks for sharing this great article.reparacion moviles

The weighted sum of these three actions is used to adjust the process via a control element such as the position of a control valve or the power supply of a heating element.reparar moviles

A current client of mine will be relocating to your area and wanted me to find a practice to suit their family’s needs. Based on your website and your online reviews this looks like best practice for them. Keep your eyes open for the Jacobsen family!

Hi, I found your post extremely useful. It helped Maine all the method in finishing my assignment, i'm additionally giving a referance link of your journal in my case study. Thanks for posting such informative content. Keep posting.

I am very happy to be here because this is a very good site that provides lots of information about the topics covered in depth. Im glad to see that people are actually writing about this issue in such a smart way, showing us all different sides to it. Please keep it up. I cant wait to read whats next.

But, as I said earlier, we must accept that there are two sides of every aspect or a thing, one is good, and one is bad.

woom manstab sekali postingannya, memang gak salah lagi tipikial engineer selalu kayak gini. Salam dari Bali pak,

PID wis lali kabeh mas...

ga mudeng niee...kurang mengertiiiiii gan..

The web is so full of garbage it's becoming difficult to find exactly what you are looking for nowadays

binggung....tapi Cocok buat referensi belajar nih...

At the beginning I thought the post was not interesting, but I have to say I was intrigued with this theme.

The web is so full of garbage it's becoming difficult to find exactly what you are looking for nowadays

I recently came across your blog and have been reading along.

If a controller starts from a stable state at zero error (PV = SP), then further changes by the controller will be in response to changes in other measured or unmeasured inputs to the process that impact on the process, and hence on the PV

jian tenan.....

buku berjalan PID rek....

aku diurui po'o....

It is not only going to be cheaper, but it will be much more beneficial to your health and your family.

Thanks for posting such informative content. Keep posting.

. I am totally agreed with your thoughts. Thanks for sharing this beautiful thoughts with me.

There are many things I can know only after reading your wonderful article.

PID controllers are the controllers of choice for many of these applications.

Thank you for the brief and complete information

I have to say I was intrigued with this theme. After read the information you posted

keep writing brother, I'm sure this blog will bigger one day couse focused to one niche.

Tuning a control loop is the adjustment of its control parameters (gain/proportional band, integral gain/reset, derivative gain/rate) to the optimum values for the desired control response.

sagf good very certainly want set of earphones which might be cozy in addition healthy head phones You

that is a function of the proportional gain and the process gain.

A treat for readers.Post like yours makes the reader want more.Looking forward to more of your work.Interesting post. Thank you for posting

terimakasih banyak atas tulisannya dan postingannya, semoga sangat bermanfaat untuk kita semua para pembaca, salam hangat dari saya

Good post….thanks for sharing... Very useful for me i will bookmark this for my future needed. Thanks for a great source...

HOW CAN WE USE PID IN TEMP.CONTROLLING WITH GUIDENCE..PLS HELP ME